|

|

|

|

Warp Models Omega Destroyer

-Customized-

I have written this buildup review in the attempt to give to the intrested people some explanations about the buildup of the Omega "Brightwarrior" I did. - I am not a professional or a "semiprofessional modeller, so the oucome was satisfactory for me, but it is absolutely nothing exceptional. Anyway, I hope that this page can be useful.

This was my first resin kit, and I did not what to expect. Furtherly, i have abandoned the modelling hobby for years.

I became aware of the kit through the review on http://www.starshipmodeler.com, (see Kit review at http://www.starshipmodeler.com/b5/jl_pre_omega.htm ) and so I decided to take from the wasteland all the modelling tools, buy putty and paints, and try to build it.

The Kit

I purchased the Kit at http://www.federationmodels.com through internet (here is the specific page, Federationmodels.com/warp_models/default.htm, and received it through air mail. The kit box was in another larger box, very well protected.

Preparation of the

"custom" parts

As I said, I did not want to build a Standard Omega, I wanted to

build this: Omega Brigtwarrior , and so were needed some custom special parts,

essentially the engines, the cannons and the chin mounted

antenna.

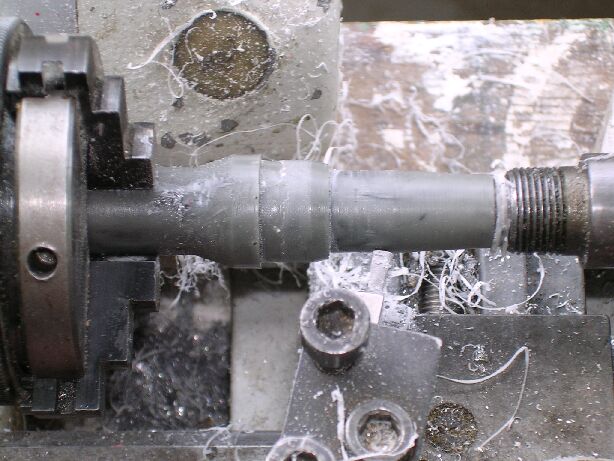

I started with the kit engines, cutting and modifying them on a

lathe. With the same lathe I made the larger engine terminal

nozzles, starting from an aluminium tube. The assembly was easy (

I made the work to allow a good fitting between modified original

engines and aluminum made nozzles ) and the outcomes, IMO, good.

ENGINES - BUILDING SEQUENCE

|

||

|

|

||

|

CANNONS AND TURRETS - BUILDING SEQUENCE

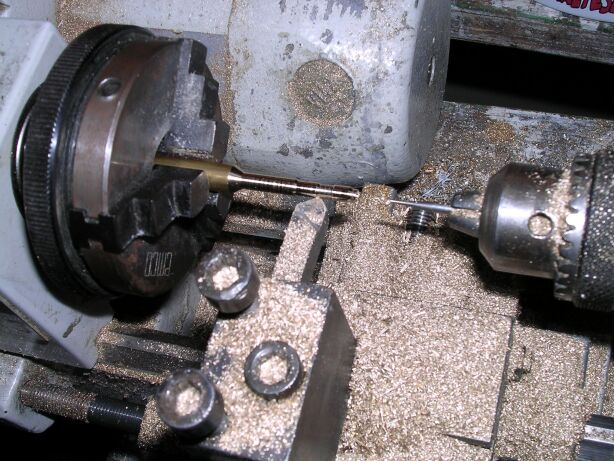

The next step were the barrels of the cannons,

even these made with the lathe from a brass rod. One thing that I

did not take into account is that, beyond the 4 bow mounted heavy

cannons, there were 12 twin turrets, and this means 4+24 barrels

- If You find relaxating to work with a lathe, it is ok,

elsewhere making a master and building them with resin is surely

faster, while IMO a building with plastic pipes or similar can be

even more time-consuming than the lathe work. Anyway, honestly

the lathe-milled brass cannons are very beautyful.

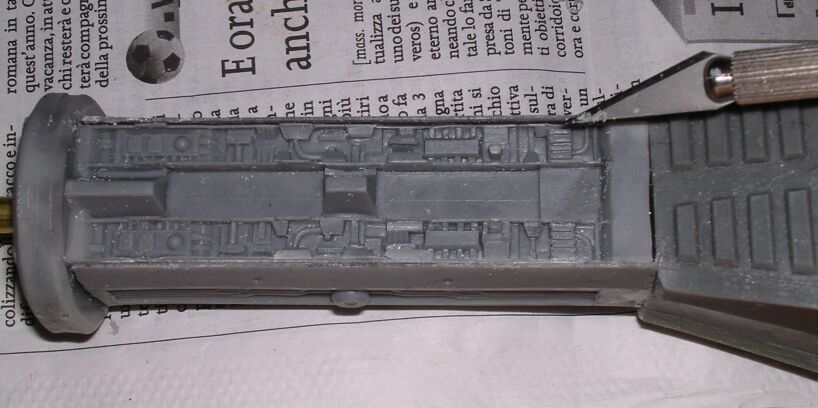

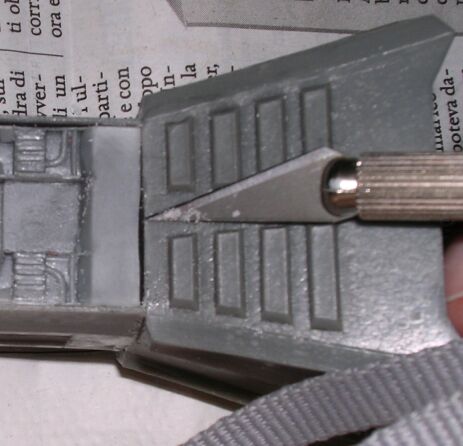

The side turrets were my first

resin work - I made a master of Evergreen styrene sheet, made a

silicone rubber mold and begun to produce turrets - The resin

must be mixed very well, elsewhere you risk to have a piece that

does not solidifies, and at this point the mold is destroyed -

Molding parts so small with a single mold means that at least an

half of the resin You use will be lost, anyway the total quantity

used is less than a couple of spoons...

AND REMEMBER TO LUBRICATE THE MOLD BEFORE EACH CASTING!

The resin cast turrets can be cleaned from the flashes with the

x-acto knife, then can be finished with files and eventually some

putty and sandpaper.

The "twin barrels" of

the side Ion cannons were glued together with superglue on a

glass plate to ensure that they were parallele, then glued in the

cast turrets. The Small details of the turrets were made of sheet

styrene strips.

|

||

|

ASSEMBLY OF THE HULL

I proceeded with the following phases:

Assembly of the forward and rear hull - Assembly of the rotating

section, assembly of the engineering section (except the engines)

and building of the rear part, engine assembly, detailing and

painting, final details and antennas.

The main hull sections assembly is conceptually straightforward,

but to hold them exactly in place when the superglue fits

requires or four hands or a good quantity of patience and some

rubber bands - The dry fitting of the parts and the eventual

previous adjustements to be made with files and sandpaper is

essential. I suggest to assemble three sides of the hull with one

bulkhead, and after set in place the fourth sideand the other

bulkhead.

Most of the parts fits very well

There are some seams that must be filled with putty and sanded -

nothing exceptional - overall it fits well.

The forward "hammer" was much more easy than one can

expect, the instructions provided are excellent and the parts

fits well, requesting only minor adjustements.

The engine section is a problem: while the halves and plates that

build up the engine block (the truncated pyramid armoured piece),

after some dry fitting and minimal adjustement comes out pretty

well, the rear plate that would have to hold in place the four

engines, the engine cradles and the rear cannons was warped, and

each engine pointed at a differnt location of the universe,

instead to be parallele: my suggestion is to use this

"engine bulkhead" in the assembly of the rear block,

then remove it and replace it with a part made of sheet styrene,

that it is planar, and so allows a decent engine assembly: a

styrene sheet "clone" of the original bulkhead is IMO

the best solution, it is faster to build than to try to eliminate

the warping of the original part, and a plane bulkhead is

essential to allow a decent engine assembly.

I did this, with a plate of evergreen sheet styrene 1.5mm thick,

with reference holes for pins of the engine cradles.

I have found the engineering section, the cluster of the four

engines and of the four rear cannons to be the most difficult of

the kit. Must anyway be remarked that the details of the parts

are excellent.

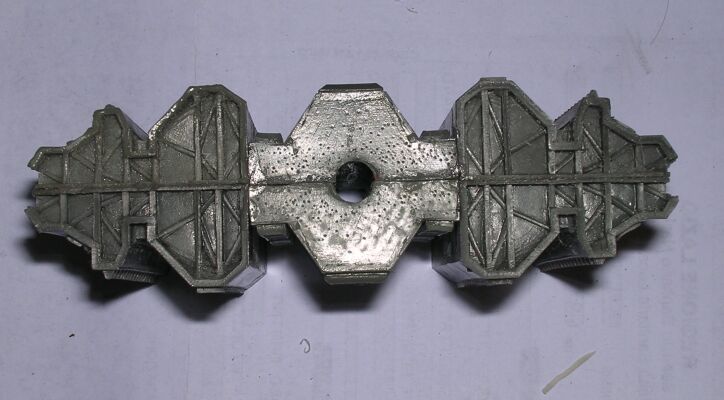

The rotating section is easy - six large resin parts, they must

be dry fitted, then can be assembled.

For the whole kit I used superglue (Cyanoachrilate), but for the

rotating section I used essentially epoxy glue, to pre-fill the

seams and allow a superior useful adhesive surface: as can be

seen in the figure, the epoxy glue works well, some putty will

fill the joints pretty well, but most part of the seams are yet

filled by the epoxy.

The final assembly with the

central brass tube that holds everything together is

straightforward, but pay attention to quickly aligne the rear and

forward assembly before the glue fits.

The side cannons of the "true" Omega are placed in a

position in which their primary targets are parts of the ship

they must defend - I made the sponsons where are placed the side

gun mounts with sheet styrene stripes. Even the supports of the

more backwards main cannons placed on the sides of the hammer are

made of Evergreen 1/4" styrene tube and styrene sheet.

I put in place the cannons and the antennas after the painting

job - The white metal antennas fits well, the steel rod ones

require to drill a couple or so of holes with a 1mm drill bite -

Set your dremel at the slowest speed, or use a hand hobby drill -

the resin is not very hard, and a fast drill will melt it or make

craters instead of holes.

The chin mounted long gravitic antenna, the one with the two

black bulges at the ends, is built with 5/32" styrene tube,

while the bulges are aluminium parts, about 5.5mm of diameter

made with the lathe.

Painting and Finishing

I Wanted a paint scheme recalling the "Shadow Armour"

seen in the show (The "Omega Epsilon" is a ship of the

2270's, developed in the hottest period of the Drakh War, and the

Earth Alliance put in it every bit of technology she was able to

develop, steal or recover).

Most part of the painting was done with a Badger Air Brush and

acrylic paints - A step forward respect to the Enamels I knew

when I was a boy -

I painted the whole model with a layer of Tamiya Acrylic primer

(spray can) and with a layer of Tamiya acrylic light grey XF-66 -

The black pattern of the "Shadow -derivated Armour" is

airbrushed with Tamiya matt black XF-1. The airbrush was setted

to spray a very thin stream.

Some details, like the bases of the antennas, the sensor domes

and the chin mounted oval plasma mortars are painted in a darker

grey, XF 24 dark grey - the red parts like the inner part of the

hangar and the side mounted hatces of the escape lifepods are

painted in XF-7 flat red, with a brush.

The barrels of the cannons are XF 24 dark grey, and X-10 Gun

metal for the recessed belts. The placement of the cannons was

the last step of the assembly, the decals were excellent, while I

made easily the nameplate drawing it with Microsoft Paint - I cut

the "nameplates" from the paper sheet I painted them

on, then I put them on a strip opf two-sided adhesive scotch and

covered them with normal scotch - cut them at the right

dimensions and then apply on the finished model.

Overall, a decent work, but nothing more: some weathering would

improve a lot the model, showing better the details.

The base is a simple perspex (plexiglas) plate in which I made

two holes - I made the conical support columns with the lathe,

drilled one 2.5 mm. hole under the belly of the ship to hold a

spine placed on the rear column, while the forward column has not

a spine, the model simply rests on it.

Overall, I have found this an excellent kit, amusing to build. A bit more attention to avoid the warping of the main structural parts would be welcome, but the kit as a whole is fine, in excellent accordance with the original of the series, even if not to be recommended to a beginner due to the large number of parts and, I presume, to the intrinsecal difficulties of a resin kit. Anyway, after this building, I have bought even the Warp Model's Nova Dreadnought - This can be a clue that the outcome and the satisfaction, at least for me, deserves both the expense and the effort.